Industrial waste sulfur transformed into cutting-edge material for next-generation robotics

A research team led by Professor Wie Jeong-jae of the Department of Organic and Nano Engineering, in collaboration with Professor Kim Yong-seok of Sejong University and Dr. Kim Dong-gyun of the Korea Research Institute of Chemical Technology, has successfully developed the world’s first soft robot made from industrial waste sulfur. The breakthrough is especially significant for demonstrating how waste-based materials can be integrated into next-generation robotics.

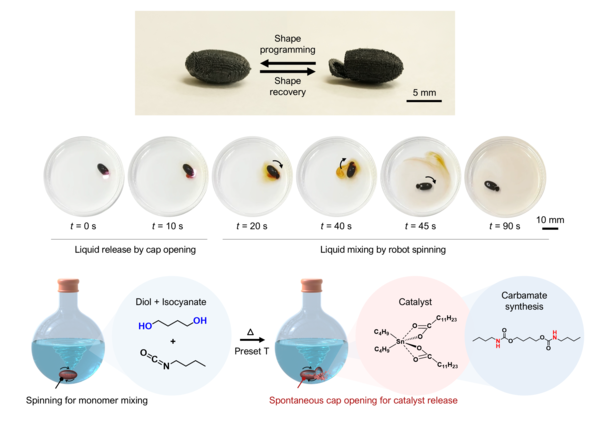

The team synthesized a sulfur-based polymer using elemental sulfur—commonly discarded as a byproduct of petroleum refining—and created a composite with magnetic particles to formulate a novel ink for 3D printing. This ink, designed for Direct Ink Writing (DIW), enables precise fabrication of soft robots in desired shapes. Once printed, the robots respond to magnetic fields for remote-controlled movement, exhibit shape-memory programming and photothermal effects for shape transformation, and can be reheated for bonding and recycling, offering both functionality and sustainability as a circular robot material.

Building on this foundation, the team also designed a capsule-type soft robot embedded with chemical catalysts to enable intelligent control of chemical reactions. Inside a chemical reactor, the robot functions as a magnetic stirrer and, upon reaching a programmed temperature, autonomously opens its capsule to release the catalyst—triggering the chemical reaction remotely and precisely when needed.

“This achievement lies in transforming sulfur polymers, known for their chemical resistance and strong photothermal responsiveness, into a multi-stimuli-responsive intelligent robotic platform,” said Professor Wie. “It presents a sustainable material processing strategy that upgrades waste into high-tech robotic applications.”

The results of the study were published online on July 17, 2025, in Advanced Materials (Impact Factor: 26.8), a leading international journal. The research was supported by the National Research Foundation of Korea and the U.S. Army Research Laboratory. The paper, titled “Closed-Loop and Sustainable 4D Printing of Multi-Stimuli-Responsive Sulfur-Rich Polymer Composites for Autonomous Task Execution,” lists Dr. Won Soo-kyung of the California Institute of Technology as co–first author, Dr. Jo Woong-bi (Department of Organic and Nano Engineering, Hanyang University) as co-author, and Professor Wie Jeong-jae as co–corresponding author.

'한양위키' 키워드 보기

'한양위키' 키워드 보기