A joint research team led by Professor Wie Jeong-jae of the Department of Organic and Nano Engineering at Hanyang 토토사이트 제작 데이터베이스, Professor Kim Chae-bin of the Department of Applied Chemical Engineering at Pusan National 토토사이트 제작 데이터베이스, and Professor Jeong So-dam of the Department of Chemical Engineering at Dong-Eui 토토사이트 제작 데이터베이스 has developed a multi-stimuli smart material responsive to magnetic fields, light, and heat. This material successfully reproduces the complex 3D structure of shark skin riblets.

Sharks possess microgroove structures known as riblets on the surface of their skin, which help reduce frictional resistance and enable swift, flexible movement through water. Inspired by this, 토토사이트 제작 데이터베이스ers have long explored applications in aerospace and sportswear. Notably, in the 1980s, NASA tested artificial shark skin on aircraft, and during the 2000 Sydney Olympics, a swimmer won three gold medals wearing a full-body swimsuit modeled after shark riblets.

However, the intricate, overlapping 3D morphology of real shark skin posed a challenge for accurate reproduction using conventional technology. In 2024, Professor Wi’s team received international attention for a novel approach published in Advanced Materials—they fabricated riblet structures by applying a magnetic field to an elastomer infused with magnetic particles, then fixed the form using a heat-curable polymer resin.

Yet that method had limitations: controlling the exact amount of resin applied was difficult, and the resin often filled the fine gaps between microstructures, compromising structural fidelity. Additionally, once fixed, the structure could not be reconfigured.

To overcome these limitations, the joint 토토사이트 제작 데이터베이스 team has now developed a new smart material capable of real-time shape fixing and release via light stimulation. The material is built on disulfide bond-based covalent adaptable networks (CANs), whose molecular bonds rearrange upon exposure to light.

The researchers conducted a detailed analysis of the material’s mechanical properties and stimulus responses to light and heat, and confirmed the underlying mechanism at the molecular level using molecular dynamics simulations.

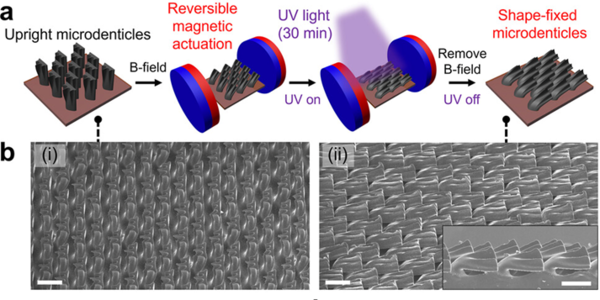

The 3D structures were fabricated using microtextured surfaces containing magnetic particles embedded in the disulfide-based CAN. When subjected to an external magnetic field, the structure flexibly deforms in a controlled direction. Upon light exposure, dynamic disulfide bonds within the material respond by relaxing the internal stress and fixing the shape. By altering the magnetic field and reapplying light, the structure can be reconstructed into a new form—enabling repeatable shape reconfiguration.

This technology is seen as a significant advancement, overcoming previous challenges by allowing both precise biomimetic fabrication and reversible structural control.

The research was supported by the National Research Foundation of Korea. PhD candidate Yoon Yeo-myeong (Pusan National University) and integrated master’s and PhD candidate Moon Ho-jun (HYU) served as co-first authors. Postdoctoral researcher Cho Woong-bi (HYU) and master’s student Lee Dong-uk (Dong-Eui University) participated as co-authors. Professors Kim Chae-bin, Jeong So-dam, and Wi Jeong-jae served as corresponding authors.

The 토토사이트 제작 데이터베이스 article, titled “Light-Fueled In-Operando Shape Reconfiguration, Fixation, and Recovery of Magnetically Actuated Microtextured Covalent Adaptable Networks,” was published online in Advanced Materials on June 1 and was selected as the journal’s front cover article in recognition of its excellence.

Click to read the paper:

https://advanced.onlinelibrary.wiley.com/doi/full/10.1002/adma.202503161

'한양위키' 키워드 보기

'한양위키' 키워드 보기